Excess inventory is inescapable. It’s a fact of the CPG supply chain life and will always be around as long as we continue to operate in a linear economy system.

So why do companies lose money on closeout programs? The answer is simple: because they don’t have the right tools at their disposal. Failing to digitize closeouts results in loss and waste - but with today’s technology, there’s no reason why you should accept the amount of risk and financial loss your current closeout program creates.

Adapt and evolve - or go extinct

In this day and age of technology, the simple fact is if you’re not willing to adapt your current manual processes, you’re going to be left behind. It’s a matter of evolving or going extinct.

A well-known example of this problem could be seen with Blockbuster, which declined Netflix’s offer in the early 2000s and ended up filing for bankruptcy, illustrating how an unwillingness to digitize can cause financial losses and even failure.

Supply & Demand Chain Executive found that only 1 in 4 CPG companies has adopted at least one digital solution across their supply chain. Think of it as the survival of the fittest of the CPG industry - if you’re not in the 25% of CPG companies leveraging digital tools, you wouldn’t be considered the “fittest.”

So let’s apply this thought to discounting and closeout processes and how adapting to an ever-changing technological world will benefit your company, especially as 72% of closeout teams recover 50% or less of their costs.

1. Streamlined communications

One of the most obvious ways digital tools can reduce loss is by streamlining communications, both with internal and external teams.

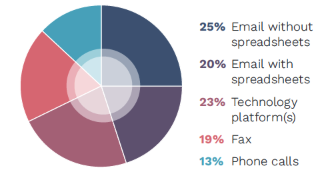

It may be hard to believe, but a vast number of companies still rely on outdated communication methods such as faxing in order to communicate available inventory and negotiate offers with their buyers. In fact, 77% of CPG companies rely on emails, faxes, and phone calls to communicate with secondary market buyers while only 23% already leverage technology platforms.

Automating administrative and manual tasks increases productivity that can be used for additional investments in innovation or time spent nurturing and improving upon existing customer relationships. As a result, you can engage secondary market buyers more effectively.

Let’s throw in a hypothetical where Jeff, who is running the closeout program, handles communication solely through emails, phone calls, and spreadsheets. Not only does it take more time and effort for Jeff to handle this manually across a variety of buyers, but it forces him to offer inventory in a waterfall approach. Simply put, this means that Jeff communicates with Buyer #1 on Monday, waits for their response, and if declined, goes to Buyer #2 a few days later, and so on. Wouldn’t it be easier to use a platform that allows Jeff to have the option to submit offers to all relevant buyers at once or still be able to use a waterfall, or tiered, approach if necessary?

Communication is key in managing supply chains and closeouts as it keeps everyone informed about current developments and updates, which reduces risk at every level: supplier risks are reduced through better visibility into their operations; distributor risks are reduced because they know when they need more stock; retailer risks are reduced because demand forecasts become more accurate, and consumer risks decrease because streamlined communications earlier on in the supply chain can allow for longer shelf-life on products.

2. Increased visibility and advanced analytics

Digitizing your closeout process allows you to improve visibility and gain insights into your excess inventory. This enables you to make more informed decisions, which ultimately leads to stronger results. The data you collect is an asset; it’s only as good as the insights you draw from it. By digitizing closeouts and using advanced analytics that tools like Spoiler Alert offer, you’ll be able to spot trends and opportunities that otherwise may have gone unnoticed. Additionally, you can more easily track the KPIs that matter most to your organization.

Your leadership team may not even be aware of how much money is being lost on excess inventory. After all, it’s not just the product you’re losing if the inventory hits its expiration date, you’re losing money on the labor, storage, materials, packaging, and more that went into creating that product in the first place.

By making data accessible to the larger team, you can prioritize the factors that are causing financial losses. Advanced analytics can also deliver valuable insights when assessing potential sales opportunities.

3. Avoiding manual errors

When you don’t have real data in real time, it’s hard to determine what you’re actually working with. Manually inputting sales data into systems such as Excel can easily create errors in reporting, especially if multiple people are doing this work.

Overlooked errors can cause major financial losses. The additional time, resources, and budget required to find and correct mistakes are among the hidden costs of these manual human errors. You can imagine how easy it could be to lose or duplicate an invoice, which can lead to a customer not being billed or being charged double, which can drastically hurt your relationship.

4. Supply chain resiliency

Leveraging technology is especially critical in the supply chain industry due to its mercurial nature wherein seasonality, promotions, new products, and external demand changes such as weather and market conditions can create a lot of unknowns and impact your business’s financials.

This can be especially problematic for companies that are heavily dependent on inventory and have little buffer to deal with unplanned events.

Digitizing closeouts helps manage some level of uncertainty by enabling you to plan ahead so you can prioritize and handle what’s necessary. You can use digital tools to collaborate with the right people at the right time—and enable them to take immediate action if necessary—so that nothing falls through the cracks or gets left behind when it shouldn't.

Even though many supply chain disruptions are beyond the control of an individual employee, businesses can still be proactive and prepare for them better with tools.

While you may have one-off solutions to reduce risk, leveraging digital tools is needed to have a truly resilient business in the face of an uncertain supply chain.

5. Warehouse and storage space optimization

If you're like most companies, you are probably familiar with the concept of carrying costs. These are the costs associated with keeping inventory on hand for longer than necessary. In your case, this could include excess inventory or damaged products that haven’t been sold yet. Carrying costs account for up to 20-30% of your spending and can have a significant impact on your bottom line if not managed properly.

By optimizing warehouse and storage space, you don't have to rely on throwing out products, which includes disposal costs and can create a backlash from consumers.

This is where speed to market comes in handy - when you can sell excess inventory quicker, you can increase inventory turnover at your warehouse and create more space for newer and more profitable products.

Spoiler Alert customers experience a 75% increase in speed to market through automating their closeout programs.

It's time to embrace the digital world

In a survey conducted by Deloitte, 82% of enterprises utilizing AI have gained a financial return from their investments with a median ROI of 17%.

By digitizing closeouts you can expect results like:

- Increased productivity

- Increased speed to market

- Increased sell-through rate of inventory

- Increased inventory made available to purchase by customers

- Decrease in time to conduct sales process and post-cycle analytics

- Decrease in the disposal of finished goods inventory

Organizations need to constantly re-strategize for the future so it’s important to remember that it’s not a one-and-done application of digital tools. Also, don’t forget about implementation times - the earlier you start, the faster you’ll begin to see a return on your investment.

When digital tools can automate 80% to 90% of supply chain planning, what’s holding you back from digitizing closeouts?

For more information on automating your closeout program, download our research report, Technological maturity in the secondary CPG market.

.png?width=250&name=SpoilerAlert_WhiteLogo_LeftStacked%20(7).png)