.png?width=1024&name=Learning%20the%20lingo-%204%20definitions%20related%20to%20unsold%20food%20inventory%20(1).png)

Food manufacturers, distributors and retailers are well aware of the reality that, for a variety of reasons, not all products will be sold to customers. To remedy this, companies develop strategies for recovering value from unsold inventory, often through donation and secondary markets.

The tricky part is – unlike clothing, appliances or other shelf-stable consumer goods – food’s quality is constantly changing and requires different management practices depending on where it falls on the spectrum of freshness, quality and demand. For example, pumpkin pie filling is in high demand in October and November but somewhat “useless” to have in stock in December and January.

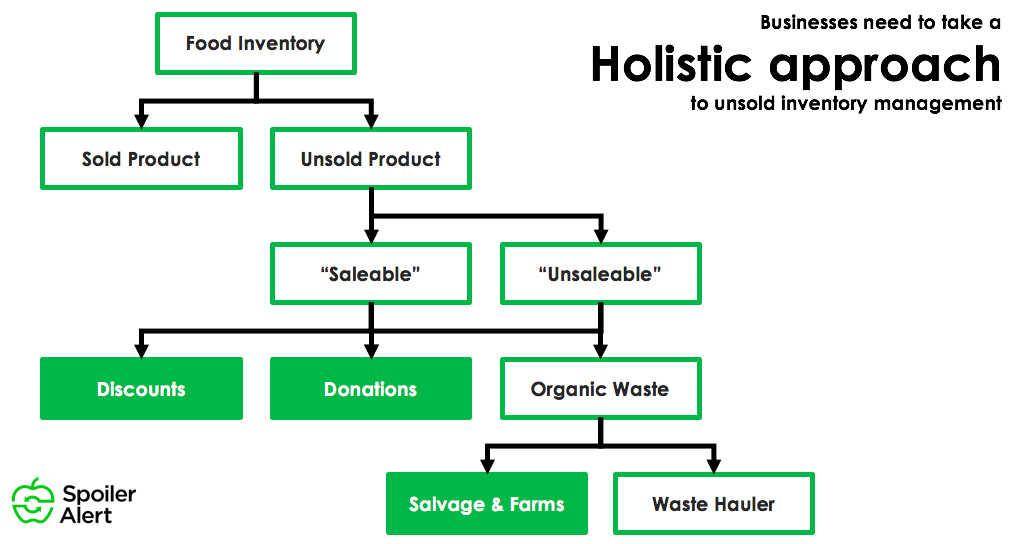

As a result, companies have to take a holistic approach to managing unsold inventory and defining processes for moving this product across various channels. In our work, we’ve found different companies use different terms and definitions for these efforts, which in turn impacts how they develop, implement and communicate their strategies to recover value from goods.

Glossary of terms

Reflecting on what it takes to establish a holistic food recovery and waste diversion program, we put together a short glossary of 3 ‘must-know’ terms for product classifications in the food manufacturing, distribution and retail sectors.

Unsold Inventory (n.)

Inventory refers to ingredients or finished product a company has on hand (often in its physical warehouses) that it intends to sell to a customer (either in its current state or through additional processing). Unsold inventory is the product that an organization intends to sell but, for whatever reason, has been unable to.

We do not refer to this product as food waste or wasted food because it is often not waste, nor is it being wasted. Instead, it’s most often perfectly good product without a market. In most cases, unsold inventory is aggregated in one central location and ready to be distributed. What’s difficult about unsold product is that it’s often influenced by changing demand forces outside a business’ control, such as weather patterns or customer purchasing fluctuations.

Consequently, despite being saleable, large quantities of unsold product end up in the landfill. The first step to scoping a company’s food recovery or waste diversion program is recognizing which product categories are applicable for donation, discounts, or animal feed markets.

Comprised of: discounted product, donations, inventory losses, shrink, unsaleables.

Distressed product (n.)

Distressed product is a subset of a company’s unsold inventory that is in jeopardy of being wasted if not managed or redistributed appropriately. Food often gets categorized as distressed due to expiration dates and either 1) clauses within customer contracts mandating a certain number of days of shelf-life, or 2) commitments by the supplier to only offer the freshest, most aesthetically-pleasing product available.

Businesses typically look to different outlet channels depending on the “level” of distress. For example, a food manufacturer might be comfortable offering product with 90 days until expiration at a 20 to 40 percent discount to its existing customers as an “opportunistic buy”. Anything between 30 and 90 days, on the other hand, might be discounted 50 to 70 percent and sold exclusively to outlets and secondary markets, so as not to cannibalize sales with its existing customers.

In almost all food industry verticals, distressed product doesn’t get the same “love” from a company’s sales reps as non-distressed product. This is because, more often than not, distressed product is discounted product, and sales reps are motivated by commissions. Finding ways to streamline the discounted sales process or incentivize sales reps to manage this product better are both effective strategies for recovering value from distressed inventory.

Alternatives: salvage; discounted; near expiration; sunset; discontinued; value channel; b-grade; aged.

Shrink (n.)

Shrink can have different meanings depending on whether it’s used in the farming, manufacturing, distribution or retail sectors. In the farming world, shrink often refers to physical shrinking – the actual contraction in size of product from exposure to temperature or moisture variations. In the retail sector, shrink usually refers to loss of product due to theft (either by customers or employees).

In our work, we most often see shrink referring to finished goods that distributors or manufacturers cannot and will not sell to anyone. This can be due to product spoilage (or surpassing a product's expiration date), product damages (such as in warehouses with forklift misoperation or breached packaging), quality considerations (such as produce aesthetics), or simply overproduction.

What these definitions of shrink all have in common is a loss of inventory, or at the very least, a loss in revenue potential from this product. Ultimately, the goal for every food business is to minimize shrink. Gaining a clearer understanding of what percentage of inventory is currently ‘shrink’ will help businesses establish a baseline for improvement.

Alternatives: inventory losses; spoilage; expired product; theft; unsaleables.

Help us expand our list!

This glossary is by no means comprehensive. Like we said, different companies use different lingo. We want to make it the best it can be, so if your company has a different definition for one of these terms, or you see a term that isn’t listed, please let us know! Over the next few months, we will be building upon this glossary on our website, so we appreciate any and all outreach.

.png?width=250&name=SpoilerAlert_WhiteLogo_LeftStacked%20(7).png)